Technicoat Group has more than 25 years of experience in applying industrial bakeware coatings.

Our experienced bakeware department advises bakeries on the best specialized coatings for their products baked goods, thereby optimising bakery productivity and product quality.

By choosing from our range of Technicoat Bakeware non-stick coatings, bakeries achieve the following benefits:

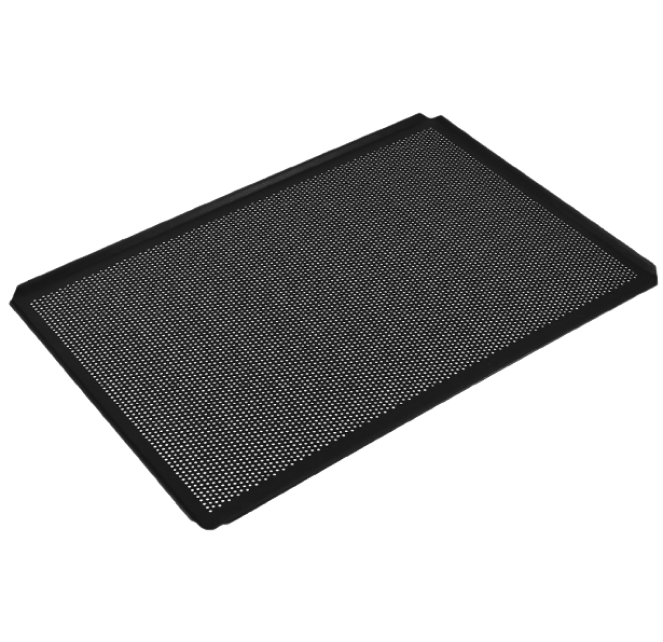

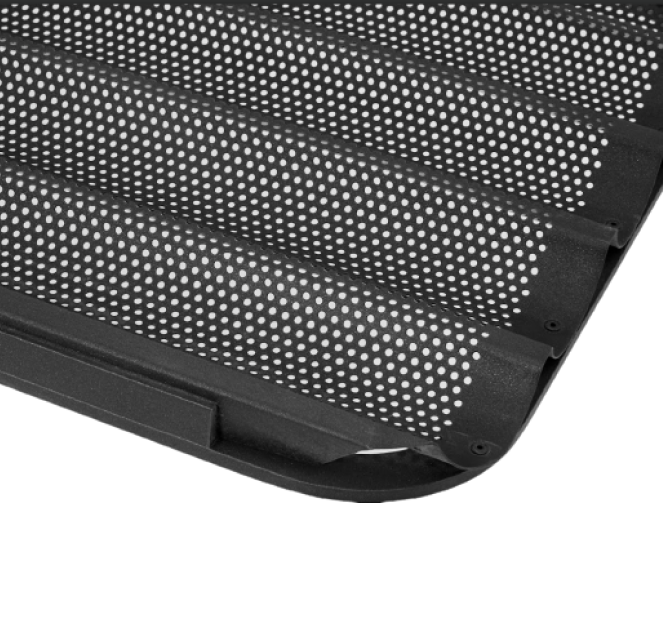

Our solution for artisanal and midsize bakeries using coated trays manually on a daily basis.

Our solution for midsize and industrial bakeries using trays manually on a daily basis or on automatic line production.

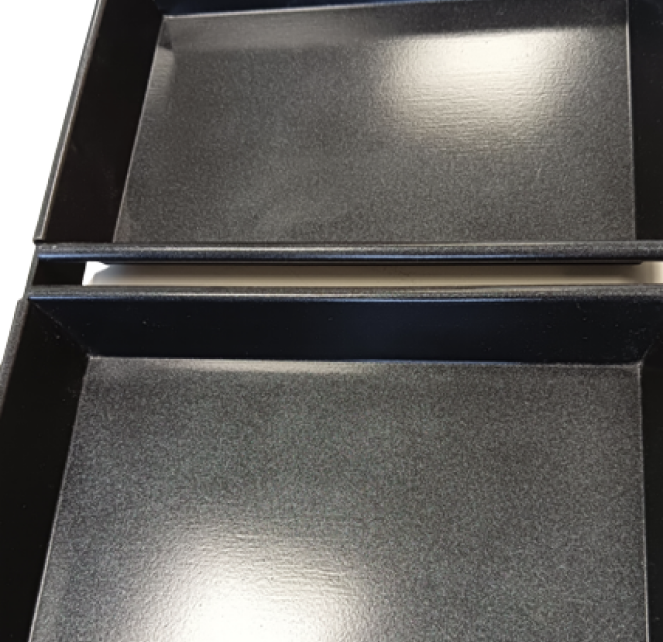

Our solution for bakeries using tin sets, bun trays, muffin trays etc.

Our solution for PFAS-free coatings based on Sol-gel technology. This coating is suitable for the food and bakery industry and is fully compliant with US and EU regulations for food contact.

Sol-gel coatings are characterized by high corrosion resistance. This type of coating is PTFE-free and it is eco-friendly.

| Type of Products | TCB ECO | TCB ULTRA | TCB SUPER | TCB CERAMIC |

|---|---|---|---|---|

| Baguette | 2 | 3 | 0 | 2 |

| Toast | 0 | 0 | 3 | 2 |

| White Bread/Rye Bread | 2 | 2 | 3 | 2 |

| Buns, Hotdog, Soft Bread, Crispy Bread | 0 | 1 | 3 | 2 |

| Milk Roll | 0 | 2 | 2 | 3 |

| Bread with Seeds | 0 | 2 | 3 | 1 |

| Laugenpretzel | 0 | 2 | 3 | 1 |

| French pastry | 0 | 2 | 3 | 2 |

| Sweet/Salty fat products | 0 | 1 | 3 | 2 |

| Sweet cake | 0 | 0 | 2 | 3 |

| Frozen products | 1 | 1 | 3 | 0 |

*Always test these recommendations before implementing into your process

| 3 | Perfectly suitable |

| 2 | Suitable |

| 1 | Suitable, as the case may... |

| 0 | Not suitable |