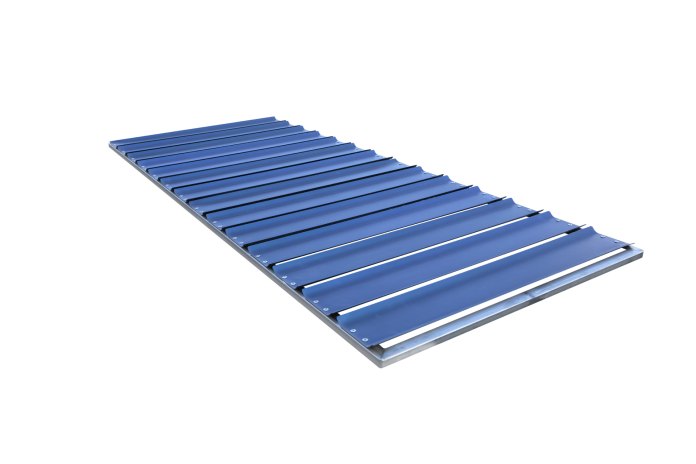

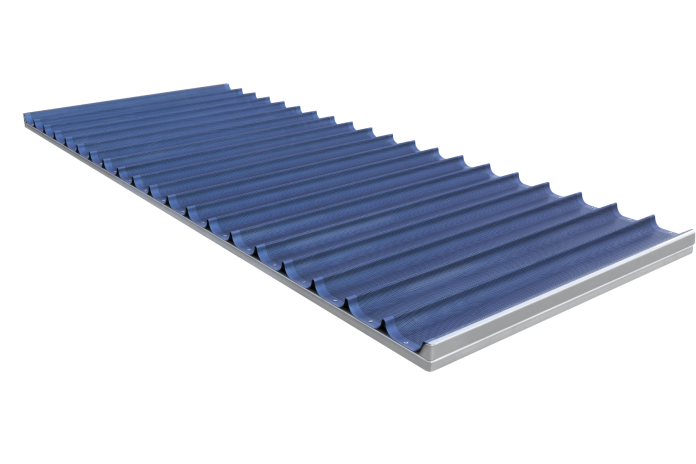

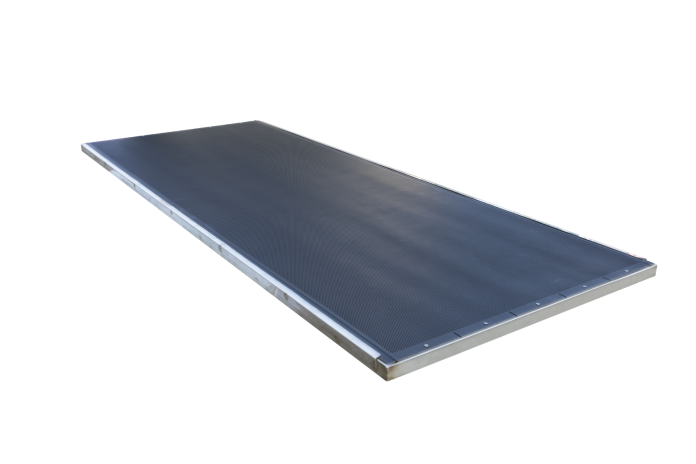

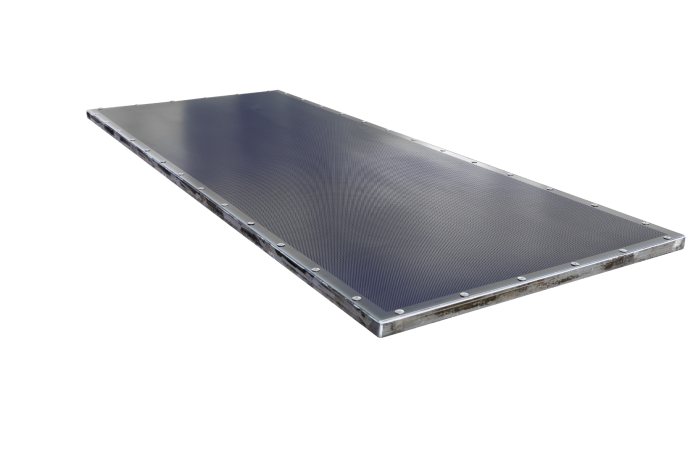

Technicoat Bakeware supplies industrial trays for automatic line production with high quality coatings adapted to your needs.

Our features

- Stable and robust stainless steel frame

- Rectangular or bended frame

- Aluminum inlays with perforation from 1,5 to 2 mm

- Stainless steel rivets

- Inlay without rivets

- Wide range of tooling’s for different kind of shapes

- Tray size up to 3m

- Stacking

- Coding

- Wide range of high-quality coatings